DC-DC Converter Step Down Non-Isolated: Efficient Power Management

In the world of modern electronics, managing power efficiently is paramount. From the smartphone in your pocket to complex industrial machinery, the ability to convert electricity from one voltage level to another is a fundamental requirement. This is where the DC-DC converter comes into play, serving as a cornerstone of power management. These devices are essential for ensuring that every component within a system receives the precise voltage it needs to operate correctly. Today, we will explore four key aspects of a particularly common and efficient variant: the DC-DC Converter Step Down Non-Isolated model.

Understanding the ‘Step-Down’ Function

A primary function of many power modules is to reduce voltage from a higher level to a lower one. This is precisely what a step down converter, also known as a buck converter, is designed to do. Imagine you have a 12V power source, like a car battery, but you need to power a component that only requires 5V, such as a GPS module or a USB charger. A step down converter efficiently bridges this gap, taking the 12V input and producing a stable 5V output. This process is crucial in countless applications, preventing damage to sensitive electronics that cannot handle higher input voltages and ensuring optimal performance by delivering a steady, regulated power flow.

The Significance of ‘Non-Isolated’ Design

The term ‘non-isolated’ refers to the electrical architecture of the converter. In a non-isolated DC-DC converter, the input and output circuits share a common ground connection. While isolated converters provide a complete electrical barrier between the input and output, which is critical for some high-voltage or medical safety applications, the non-isolated design offers significant advantages in other scenarios. The primary benefits are higher efficiency, a smaller physical footprint, and lower manufacturing costs. By eliminating the need for a transformer, a non-isolated DC-DC converter minimizes energy loss, making it an ideal choice for battery-powered devices and systems where energy conservation is a top priority.

Essential Features in Modern Converters

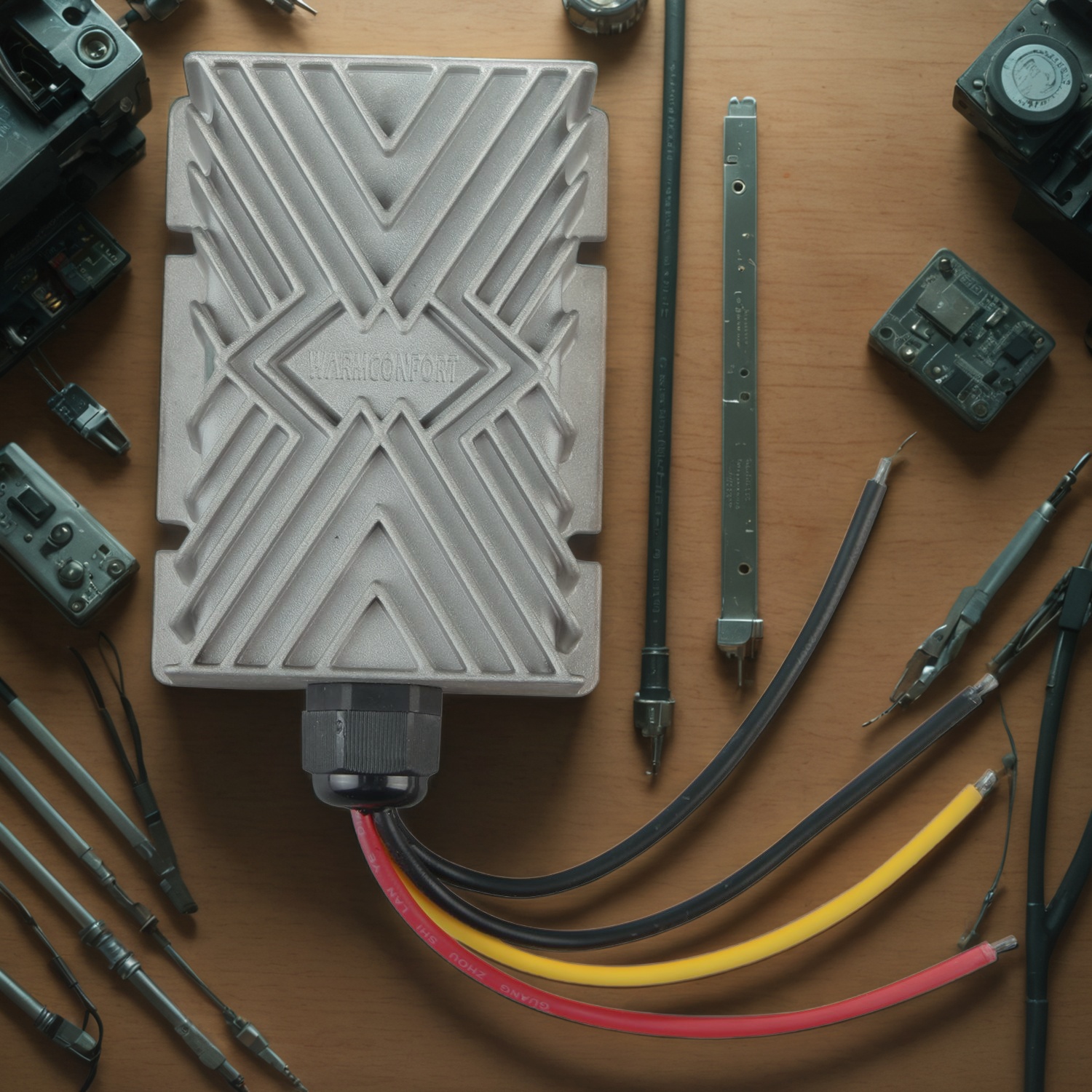

When selecting a DC-DC Converter Step Down Non-Isolated unit, its physical design and build quality are just as important as its electrical specifications. High-performance models are often encased in robust metallic or aluminum alloy housings. This isn’t just for aesthetics; the casing acts as a crucial heat sink, dissipating thermal energy to maintain stable operation. Many feature intricate grooving or sculpted fins on the surface, which increase the surface area for superior cooling. Furthermore, ease of installation is a key consideration. Look for converters with clearly color-coded wiring—such as red for power, black for ground, and a third color for signal or output—which simplifies integration and reduces the risk of connection errors.

Where Are These Converters Used?

The versatility of these components means they are found in an incredibly wide range of applications. In the automotive industry, they power everything from infotainment systems to onboard sensors. In industrial settings, they are used to control motor speeds and provide stable power to control panels. They are also integral to consumer electronics, renewable energy solutions like solar charge controllers, and robotics. In each of these fields, the converter functions as a reliable DC-DC power supply, ensuring that every part of the system operates efficiently and safely. The combination of efficiency, compact size, and cost-effectiveness makes the non-isolated step down converter a go-to solution for engineers and hobbyists alike.